Compression Test Jigs for Composite Materials

Features:

- For compression testing fiber-reinforced plastics and composite materials

- Converts a compressive force into a shear force along the wedge grip-specimen interface

- Two versions: an ASTM D3410 compliant jig and an ISO 8515 and JIS K7076 (method B) compliant jig

- 20 kN (4,400 lbf) maximum capacity

Relevant Materials:

Plastics, Composites

Relevant Standards:

ASTM D3410, ISO 8515, JIS K7076 (Method B)

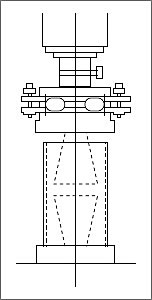

These test jigs incorporate wedge grips to apply a compressive force to a flat specimen as a shear force along the wedge grip-specimen interface. They are used for testing fiber-reinforced plastics and other composite materials. Two jigs are available: an ASTM D3410 compliant jig and an ISO 8515 and JIS K7076 (method B) compliant jig. A 100 mm (3.9 in) diameter spherically seated compression plate set is required to apply the compressive force to the jigs.

Both compression test jigs for composite materials consist of wedged grips, a grip-setting gauge, tapered sleeves, a cylindrical guide, and a specimen removal kit. The tapered sleeve and cylindrical guide provide stability to the jig and the tapering between the grip and the sleeve prevents chuck slippage, which ensures accurate testing.

Kits comprising a compression test jig for composite materials, a spherically seated compression plate set, and a compression and bending loading jig are available in some regions. Please contact your local Shimadzu representative for details.

Additional items needed for operation:

- 100 mm diameter spherically seated compression plate set