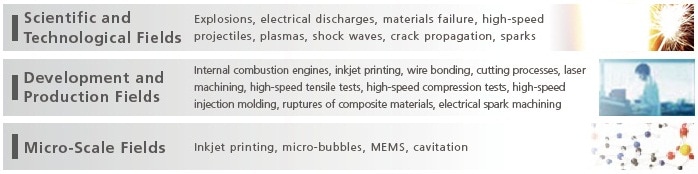

Hyper Vision HPV-X2 - Приложения

High-Speed Video Camera

Most of the documents on the LITERATURE is available in PDF format. You will need Adobe Acrobat Reader to open and read PDF documents. If you do not already have Acrobat Reader, you can download it free at the Adobe's Website. Click the GET ADOBE READER icon on the left to download a free copy of Adobe Acrobat Reader.

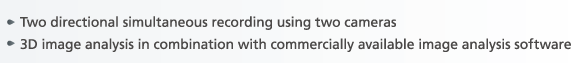

High-Speed Synchronized Recording Function Using Two Cameras

Accurate synchronized recording can be performed using two cameras at a frame rate of 10 million frames/second, so high-speed phenomena can be recorded simultaneously from two directions. Also, 3D image analysis can be performed in combination with commercially available image analysis software.

Two Directional Simultaneous Recording of the Breakage of Carbon Fiber Reinforced Plastic (CFRP) in a Tensile Test

Recording speed: 1 million frames/second

・ The behavior of plasma in plasma generators

・ Observation of the failure process of semiconductor devices

High-speed cameras are used for failure mode analysis, including observations of the moment of destruction of the insulating film on the semiconductor devices.

Dielectric breakdown of the semiconductor device

Dielectric breakdown of MOS (Metal - Oxide - Silicon, the basis of semiconductor integrated circuit) device is observed. The breakdown process is captured in which the thin-film metal electrode is going to peel from the oxide film while emits a flash.

(Provided by the Sugawa Kuroda Laboratory at Tohoku University)

Recording speed: 1 million frames/second

Width of field of view: Approx. 0.8 mm

・ The failure behavior of automotive body materials

・ The combustion process in engines

・ The injection process in fuel injection equipment

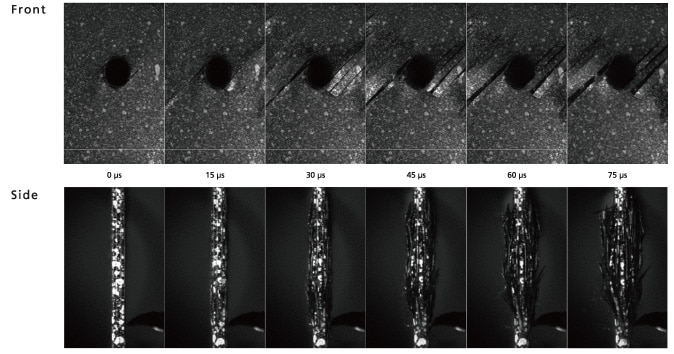

In order to develop high-output, high-efficiency automobile engines, detailed observations and analyses of the structural components of the engine are required. This includes the process of fuel injection by fuel injection equipment (injectors), and the process of fuel ignition by spark plugs.

In addition, the development of automobile bodies utilizing new materials such as lightweight and very strong carbon fiber reinforced plastics (CFRP) is actively being pursued. However, in developing such new materials, it is necessary to observe and analyze the deformation and failure behavior of materials when they undergo an impact.

In recent years, the deformation behavior of materials recorded using high-speed cameras has been analyzed using image analysis software. Dynamic analyses of the 2D or 3D strain distributions in the material are also performed.

In addition, high-speed cameras are used to observe the engine combustion process and the behavior of airbags.

Observation and Analysis of Engine Components

Discharge of spark plug or fuel injection from the nozzle can be observed in part alone or by visualization engine and analyzed in detail.

Fuel Injection Nozzle (Injector) for an Automobile Engine

Liquid fuel is injected from the engine's fuel injection nozzle. Analysis of the process of atomization, by which the fuel is changed into fine particles of uniform size, is indispensable for the development of high-power, high-efficiency engines. The images illustrate how the liquid fuel injected at high speed from the pores in the nozzle tip forms a cone-shaped film, which then changes into droplets.

(Provided by Professor Kawahara of Okayama University)

Recording speed: 2 million frames/second

Width of field of view: Approx. 1.2 mm

Fuel Injection Nozzle

Atomization Process of Fuels

The liquid fuel injected from the nozzle is captured. The liquid film turns into the droplets with increasing distance from the nozzle.

(Provided by Professor Kawahara of Okayama University)

Recording speed: 10 million frames/second

Width of field of view: Approx. 1.2 mm

Atomization Process of Fuels

Atomization Process of Fuels 1 mm from the nozzle

Atomization Process of Fuels 2 mm from the nozzle

Spark Plugs

The recorded image shows the spark discharge occurring between the electrodes of the spark plug. It is evident that the spark is bent significantly by the impact of the fuel injected from the left side to the right side of the image.

(Provided by Professor Kawahara of Okayama University)

Recording speed: 1 million frames/second

Width of field of view: Approx. 30 mm

Spark Plugs

High-Speed Tensile Test of Carbon Fiber Reinforced Plastics (CFRP)

The image illustrates the breakage of the CFRP by the high-speed tensile testing machine. The CFRP fractures instantaneously at the limit load, so a recording speed of 10 million frames/second is required to capture the fracturing process in detail.

Recording speed: 10 million frames/second

Width of field of view: Approx. 10 mm

High-Speed Tensile Test of Carbon Fiber Reinforced Plastics

Dynamic Observation of Strain Distribution in High-Speed Tensile Test

The fracture behavior of resin test pieces with various geometries was observed in a high-speed tensile test, and the strain distribution of the test piece surfaces was visualized by a DIC analysis of the high-speed images captured in the test.

(1) Dumbbell test piece

Test speed : 10 m/s

Framerate : 250 kfps

(2) Test Piece with Hole

Test speed : 10 m/s

Framerate : 1 Mfps

Test speed : 10 m/s

Framerate : 5 Mfps

(3) Notched Test Piece

Test speed : 10 m/s

Framerate : 1 Mfps

Test speed : 10 m/s

Framerate : 5 Mfps

Industrial Equipment Fields

・ Observation of the machining process in welding equipment and machining equipment

・ Operation error analysis of manufacturing equipment

High-speed cameras are used to observe and measure high-speed phenomena. These include the behavior of plasma in etching systems, sputtering systems and other plasma equipment, and machining processes in laser machining systems, electrical discharge machines, and cutting machines.

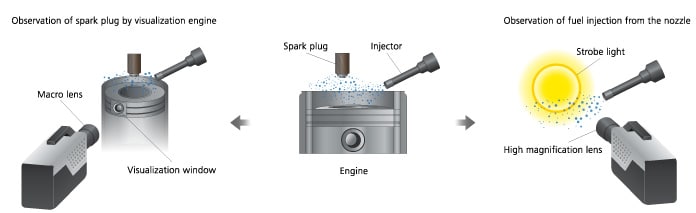

Laser Ablation Film Forming Apparatus

If the laser pulse is irradiated to a target substance, a substance surface stripped (ablation), particles with a light-emitting called plume will pop out. The laser ablation film forming apparatus utilizes this phenomenon, a substrate to be formed a film is arranged opposite to the target substance, and a film by depositing the particles generated by abrasion on the substrate. The image is obtained by observing the generation and disappearance process of the plume with the laser pulses emitted horizontally from the left.

Provided by the Tanabe Laboratory at Kyoto University

Recording speed: 10 million frames/second

Width of field of view: Approx. 50 mm

Laser Ablation Deposition System

・ The drug release process in drug delivery systems

・ The generation and disappearance process of microbubbles, which are utilized for sterilization and ultrasound diagnosis

In medical treatment and biotechnology fields, research is advancing using the dynamics of so-called microbubbles, microscopic bubbles on the order of 1 to 100 microns.

When microbubbles in a fluid are exposed to ultrasonic waves, they expand, contract, and then disappear, a process that generates a localized, high-speed flow referred to as a microjet. Research is being performed regarding the use of this phenomenon to open pores in cells so as to introduce genes and pharmaceutical agents directly into cells.

Microbubbles are extremely minute, so the process of expansion, contraction, and destruction occurs at very high speeds. Accordingly, a high-sensitivity, high-speed camera is required to analyze this behavior.

In addition, high-speed cameras are used to observe the behavior of ultrasonic waves from ultrasonic generators.

The Destruction Process of Microbubbles in Proximity to Cancer Cells Using Ultrasonic Waves

Research is advancing into a drug delivery system in which microcapsules containing pharmaceutical agents and microbubbles are introduced in proximity to cancer cells. Exposure to ultrasonic waves is used to rupture the capsules, and the pharmaceutical agents are then guided into the cancer cells. The images illustrate the expansion, contraction, and destruction of microbubbles in proximity to cancer cells, and the mechanical impact of this process on the cells.

(Provided by Division of Bioengineering and Bioinformatics at Hokkaido University)

Recording speed: 10 million frames/second

Width of field of view: Approx. 130 μm

High-Speed Contraction of Microbubbles

The images illustrate the contraction and disappearance of microbubbles resulting from an electrical discharge at the tip of a microscopic tube. Research is being conducted into micro-scalpels and other applications using the high-speed flow generated when microbubbles disappear.

(Provided by the Yamanishi Laboratory at the Shibaura Institute of Technology)

Recording speed: 1 million frames/second

Width of field of view: Approx. 0.2 mm

・ The inkjet ink discharge process

・ The failure process of reinforced glass

・ The behavior of MEMS devices used in projectors

High-speed cameras are used to observe high-speed phenomena in the micro domain. These include observations of the failure process of brittle materials such as the reinforced glass used in mobile information devices, the ink discharge process in inkjet printers, and the behavior of MEMS devices used in projectors.

Inkjet Printers

In the development of inkjet printers, it is necessary to enlarge the microscopic amount of ink discharged from the nozzle and to observe its behavior in detail using high-speed cameras.

(Provided by Associate Professor Enomoto of Kanazawa University)

Recording speed: 5 million frames/second

Width of field of view: Approx. 0.2 mm

High-Speed Video Camera

User-Friendly Software Optimized for Ultra-High-Speed Recording

Phenomena that could not be conventionally confirmed are now observable in any number of fields where high-speed recording is required. These include high-technology development, science and engineering research, biological research, and quality evaluations.

Breaking Glass - (Recording Speed 10Mfps)

Ultra-high speed and high spatial Resolution! 10 Million Frames per second - HyperVision HPV-X2 Camera. The glass is fractured by the impact of a high-speed projectile. The process of crack propagation at high speeds can be clearly observed.

Crack Propagation (Glass) Recording speed: 10 million frames/second

The glass is fractured by the impact of a high-speed projectile. The process of crack propagation at high speeds can be clearly observed.

Instantaneous Flash Lighting Recording speed: 10 million frames/second

The transmission of a spark at the instant that a xenon flash-lamp is lit can be observed in detail.

CFRP High-Speed Tensile Test Recording speed: 5 million frames/second

In CFRP materials testing with a high-speed tensile tester, the instantaneous rupture of materials can be observed in detail.

(Testing speed of 10 m/s)

Water Spray Recording speed: 4 million frames/second

The process by which the liquid sprayed at high speed from a nozzle becomes fine water droplets, and is then dispersed can be observed in detail.

MEMS High-Speed Operation Recording speed: 5 million frames/second

The high-speed displacement of the microscopic mirror in a MEMS device, used in a PC projector, can be observed in detail.

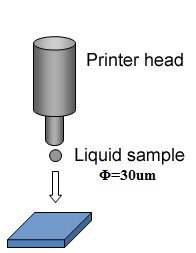

Ink Jet Discharge - Recording Speed: 5 Million Frames/ Sec

- Recording Overview

A liquid sample discharged from the tip of a printer head nozzle is observed and recorded with the HPV-X2 to show how the sample changes into a droplet and generates unnecessary spray. A high-speed video camera is required because the magnified images are taken in a microscopic area. - Application Areas

Research and development of printable electronics-related products

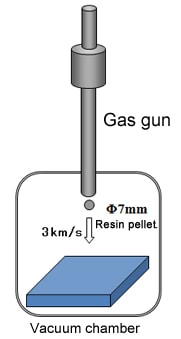

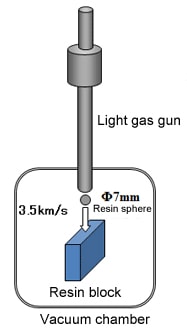

Collision of High-Speed Projectiles - Recording Speed: 10 Million Frames/Sec

- Recording Overview

This image, taken with the HPV-X2, shows the instant at which a resin pellet, fired from a two-stage light gas gun at about 3 km/s, collides with the target at high speed. It allows verifying the intense light emission from the resin pellet when it is changed into plasma by the collision, and the explosive scattering. - Recording Overview

Research and development into mechanisms that offer protection from space debris generated by space development. Investigation into meteorite collisions in space physics.

Slow motion playback of phenomena over a 25.6 μ timespan

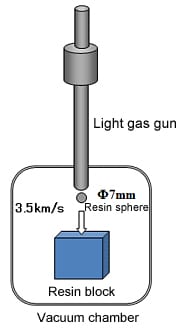

High-Speed Collision of Resin Sphere - Recording Speed: 2 million frames/sec, 5 million frames/sec.

- Recording Overview

Recorded with a HPV-X2, this image shows the propagation of stress waves and the development of cracks that occur inside a transparent resin block caused by the high-speed collision of a resin sphere fired at about 3.5 km/s from a two-stage light gas gun. - Application Areas

Investigation into material fracture mechanisms.

Slow motion playback of phenomena over a 64 μs timespan

Slow motion playback of phenomena over a 51.2 μs timespan

Destruction progress of the LED by the overcurrent

- Ultra high-speed video recording at up to 10 million fps!

- Ultra-high speed and high spatial resolution.

FP mode : 400×250 pixel (to 5 M fps,)

HP mode : 50,000 pixel (to 10 M fps,) - Maximum number of recording frames is 128 / 256

FP mode : 128 frame (to 5 M fps,)

HP mode : 256 frame(to 10 M fps,)

Milkcrown

- Ultra high-speed video recording at up to 10 million fps!

- Ultra-high speed and high spatial resolution.

FP mode : 400×250 pixel (to 5 M fps,)

HP mode : 50,000 pixel (to 10 M fps,) - Maximum number of recording frames is 128 / 256

FP mode : 128 frame (to 5 M fps,)

HP mode : 256 frame(to 10 M fps,)

Propagation of detonation

- Ultra high-speed video recording at up to 10 million fps!

- Ultra-high speed and high spatial resolution.

FP mode : 400×250 pixel (to 5 M fps,)

HP mode : 50,000 pixel (to 10 M fps,) - Maximum number of recording frames is 128 / 256

FP mode : 128 frame (to 5 M fps,)

HP mode : 256 frame(to 10 M fps,)